Call Us For Solution

+65 6570 9918

- Home

- About us

- Products

- Services

- Projects

- Contact

- COVID-19 UPDATES

Air Knocker

Stainless Steel (Flange Type)

Suitable for food and pharmaceutical, petrol-chemical …etc, where corrosion resistance and hygiene is preferred

Typical Applications

- Coffee bean roasting machines

- Resin pallet hoppers

- Ejection of film materials

- Salt & Sugar clogging

Left : Welded on hopper

Right : RKVS40 installed in salt plant

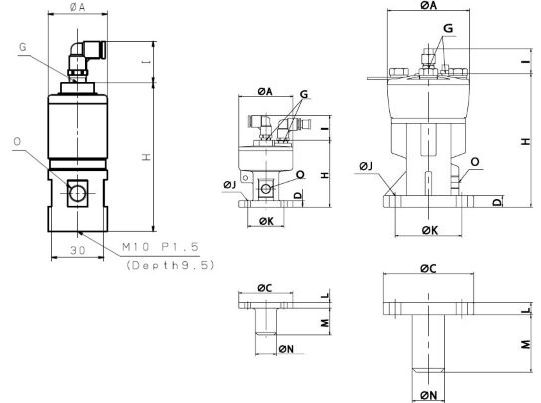

RKVS15

RKVS20

RKVS30/40P

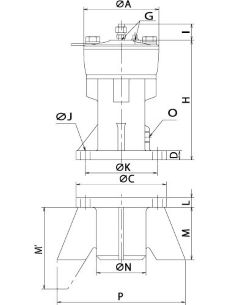

RKVS60

The impact force of the air knocker can be easily adjusted via unique valve mechanism (patented) by varying the compressed air supply.

easily adjusted via unique valve mechanism (patented) by varying the compressed air supply.

The ability to adjust the impact force will enhances the air knocker capability to work on unforeseen circumstances such as changes of material characteristic due to the process.

*The blue part is the unique “umbrella type valve”

Multiple Air Knockers operated in Cascade Connection

* RKVS15 type does not support the relay piping.

The RKVS15 can be installed with a M10 bolt. Therefore, it can be installed on your idea such as installation with the dedicated stay bracket, with no knocker mounting stay provided on the container or with no soldering of container.

The stainless steel knocker series have durability supported by high design basis and have a simple structure, which provides almost maintenance-free performance and requires no additional spare parts. In long-term delivery record of this air stainless steel knocker series, customers have appreciated its maintenance-free performance with almost no failure

| Model | Working Pressure (Mpa) | Stroke Cycle (times/min) | Air Consumption (L/time (ANR)) | Stroke Energy (N.m) | Impulsive Force (kg.m/s) | Equivalent Hammer (pound) | Mass (kg) |

|---|---|---|---|---|---|---|---|

| RKVS15 | 0.3 ~ 0.7 | 1 ~ 60 | 0.03 ~ 0.06 | 2.7 ~ 5.9 | 0.3 ~ 0.5 | mini hammer | 0.43 |

| RVKS20 | 0.04 ~ 0.10 | 4.3 ~ 8.3 | 0.6 ~ 0.8 | 0.6 or less | 0.8 | ||

| RKVS30 | 0.05 ~ 0.13 | 5.5 ~ 13.1 | 1.2 ~ 1.8 | 1 or less | 1.6 | ||

| RKVS40 | 0.15 ~ 0.37 | 9.2 ~ 22.3 | 2.6 ~ 4.0 | 1 ~ 1.5 | 4.2 | ||

| RKVS60 | 0.33 ~ 0.77 | 20.6 ~ 49.0 | 6.9 ~ 10.6 | 1.5 ~ 3 | 10.4 |

* The weight includes that of base.

| Model | ØA | ØC | D | G | H | I | ØJ | ØK | L | M | ØN | O | Tubing Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RKVS15 | 34 | – | – | 1/8 | 86 | (24) | – | – | – | – | – | Rp1/8 | Ø4 X Ø2 |

| RKVS20 | 57 | 57 | 6.5 | 70 | (26) | 6.5 | 44 | 6 | 28 | 22 | Rp1/8 | Ø6 X Ø4 | |

| RKVS30 | 60 | 70 | 8 | 95 | (25) | 8.5 | 55 | 8 | 35 | 27 | Rp1/4 | Ø8X Ø6 | |

| RKVS40 | 86 | 95 | 12 | 140 | 12.5 | 70 | 13 | 60 | 34 |

| Model | ØA | ØC | D | G | H | I | ØJ | ØK | L | M | M’ | ØN | O | P | Tubing Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RKVS60 | 115 | 138 | 14 | 1/4 | 183 | (28) | 14.5 | 110 | 15 | 80 | 120 | 76.3 | Rp3/8 | 196 | Ø8 X Ø6 |